28-01-20 // “EYES WIDE SHUT”-LIKE SCENES – INTERVIEW WITH BERND UPMEYER

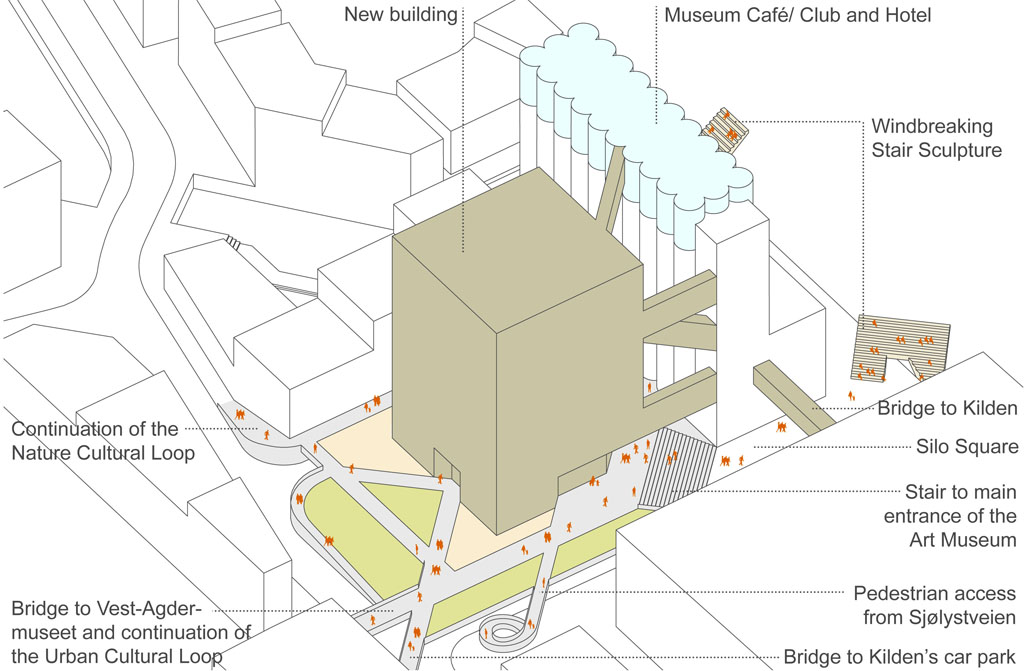

The new building for the Art Museum and Cultural Quarter in Kristiansand is connected with bridges to the existing concrete silo

Eyes Wide Shut”-like Scenes

Interview with Bernd Upmeyer

Jinyoun Na: What are some architectural projects that inspired you regarding Concrete, Stone and Steel? And why?

Bernd Upmeyer: One of the concrete buildings that left a deep impression on me, when visiting it in 2012, was Vilanova Artigas’ Architecture and Urbanism College at the University of São Paulo in Brazil. What first appeared to me as a large and roughly constructed parking garage, with all the ramps and concrete associated with it, turned out to be a fascinating, open structure for education. However, when it comes to the use of stone the closedness of the small units, mostly saunas, that are scattered around Peter Zumthor’s Therme Vals, fascinated me. There, the locally quarried Valser quartzite emphasizes the dark cave and quarry-like structures of these small, intimate spaces that are partly equipped with leather curtains and in which one might easily imagine “Eyes Wide Shut”-like scenes of some secret society. Steel is memorably celebrated in Mies van der Rohe’s Farnsworth House. When I got the chance to visit last summer, the building’s appearance with its pure, white-painted, and exposed steel structure and steel columns surrounded by an extraordinary green context made it look like a temple commemorating steel as a material, which left a deep impact on me.

View from the main square of the urban design project in Lippstadt in the direction of the Tree house café

JN: What is the favourite project you’ve designed using Concrete, Stone and Steel and why?

BU: In 2016 we took part in the competition for the Art Museum and Cultural Quarter in Kristiansand, Norway, for which an existing concrete silo had to be renovated and extended with a new building. We wanted to pay tribute to the beauty of these silos and thus tried to make them accessible through bridges from the new building as much as possible. We recently used stone as a tool in an urban design project in the German city of Lippstadt to carve out solid areas for public spaces, out of a re-imagined deep forest that covered the entire site more than thousand years ago. In order to unite two existing separate schools in the city of Geesthacht, we used the strength of steel to create a project that we called “A Real Connection: Bridge and Square”. It consisted of a 120m long and 1 floor tall bridge-building connecting both schools spatially and functionally. There, to realize the large span of the new building, without restricting the views to the outside, we proposed a structure of steel girders, commonly known as Vierendeel trusses, consisting of square frames without diagonals.

View of the “A Real Connection: Bridge and Square” project in Geesthacht from the former secondary school to the new building with the steel girders behind the facade

Concrete

JN: What concerns you the most when you construct concrete buildings?

BU: When I recently read an article in the Economist listing arguments “Why more buildings should be made of wood” in order to help reduce pollution and slow global warming criticizing the construction industry that strongly favours brick, concrete and steel, I was a bit irritated about the lack of knowledge of the sustainable qualities of a material such as concrete. The general public should be told that concrete has great qualities as a storage of heat and cold in buildings, contributing significantly to the reduction of the energy that is used for a building. Thus, increasingly, I am interested in this quality of concrete, apart from its ability to be shaped fairly easily to whatever durable stone-like form, when using it to construct a building.

JN: Please comment on Exposed Concrete.

BU: I like exposed concrete very much. Although it does not seem to be liked by too many people these days, we should not forget that it was once the favourite choice for the facades of many buildings. Ever since Le Corbusier demonstrated during the 1930s-1950s how well exposed concrete can look and work, especially in buildings such as the Unité d’Habitation in Marseille or Sainte Marie de La Tourette, its success seemed to be unstoppable. Sometimes it is hard to believe, but during late modernism using prefabricated exposed concrete panels became so fashionable that in some countries, such as in Lithuania, where that kind of concrete prefabrication was rather uncommon but admired at that time, such concrete panels were ironically casted-in-place due to the lack of factories that could produce these panels industrially, faking an industrial look of pre-casted exposed concrete. At least this is what an architectural guide told us some years ago when visiting Vilnius’ Registrar’s Office in the capital of Lithuania.

BOARD’s office space in Rotterdam with exposed concrete ceilings, 2019

JN: Tell us about the pros and cons of Concrete.

BU: Next to the abovementioned advantages of concrete – good thermal mass properties and its versatility when it comes to shapes – other well-known pros are its low production and maintenance costs, its high durability, its good water and high-temperature resistance, its good relationship with steel (due to its comparable coefficient of thermal expansion to steel) to create reinforced concrete, and its varied applicability, etc. However, what I appreciate a lot in concrete too, is its pure, bare and minimalist aesthetic, especially when applied in interiors, yet with a certain detail to it that can come, for example, through the use of wood formwork creating a wood grain image on the concrete, as is visible on the exposed concrete ceilings of our office in Rotterdam. If such detail is lacking, concrete can look easily very dull, especially when exposed to the exterior and different weather conditions, where it can easily end up looking rather dirty due to its typical plain light and monochrome grey colour, which I consider as one of the biggest disadvantages of the material. Other typical and more technical limitations of concrete include its brittleness often leading to cracks and the corrosion of reinforcements, its low tensile strength, its low toughness and specific strength compared to steel when it comes to impacts that it requires for formwork to be created, its long curing time, and that it demands strict quality control and skilled labour during mixing, etc..

Stone

JN: Have you ever used rough stone (not stone panel) in construction?

If so, tell us about the differences between two materials (rough stone and stone panel).

BU: We once used rough stone, which was in fact the remains of a medieval fortification, as part of a new entrance to the Dutch city of ‘s-Hertogenbosch. We designed a building with a green ramp as a roof around these remains with a public square in front of it, functioning as an open-air theatre. Under the green ramp we created a visitor’s centre as a transparent interior space, where the remaining rough stones of the historical fortifications could be exhibited as pieces of art. Since the exposed stone with its multiple layers of history appeared indeed as very rough, the project had a kind of natural geographic aspect to it, which related the stone strongly to its context from which the stones once might have been quarried. This aspect of rough or natural stone can be found in many projects where such material is used. On the other hand, for the project for the urban design project in the German city of Lippstadt we wanted to use treated stone appearing more artificial in contrast to the natural geography that was made out of the historically existing forest on the site. We aimed to create a hybrid place in which the city and geography would converge in a story of identity and imageability.

JN: Introduce each case of your experiences with Stone as an exterior material and as an interior material.

BU: Although the remaining rough stones of the historical fortifications for the entrance to the Dutch city of ‘s-Hertogenbosch were entirely interior, they could nevertheless be experienced from the outside of the building and their meaning reached via a graphical timeline along a path that leads visitors from the square, through the green ramp, directly into the centre of the city. Along this public path this timeline featured the history of the location. Thus, the entire project may be understood as an archaeological site that is permanently open to the public. That way, the people of ‘s-Hertogenbosch will be able to observe archaeologists during their work, whether from the outside or inside. With the stone we used for the urban design project in Lippstadt, we did not aim to create such an ambiguity when it comes to the interior or exterior. There, the stone was merely used outdoors and in particular to create an identity-forming public space and crystallization point of urban life within the district.

JN: Tell us about the pros and cons of Stone Panel.

BU: The fact that stones, and especially natural stones, have the power to relate to geography and to landscapes (due to the fact that they are loaded with meanings and originating from them) I consider a particular value of stones. Through their meaning they gain a certain narrative quality, which I think is an advantage of stones that materials such as concrete or steel are seldom able to provide, unless they were made from recycled materials. Technically, stones certainly have more benefits, such as durability, good heat and sound insulating qualities, being a non-porous and non-absorbent material, weather resistance, etc.. The fact that stone panels are fairly expensive in comparison to, for example, concrete panels, is probably its biggest disadvantage. Other cons would be related to the necessity that stone usually requires a structural substrate and can be labour-intensive and time-consuming to install, which makes it again more costly than other materials.

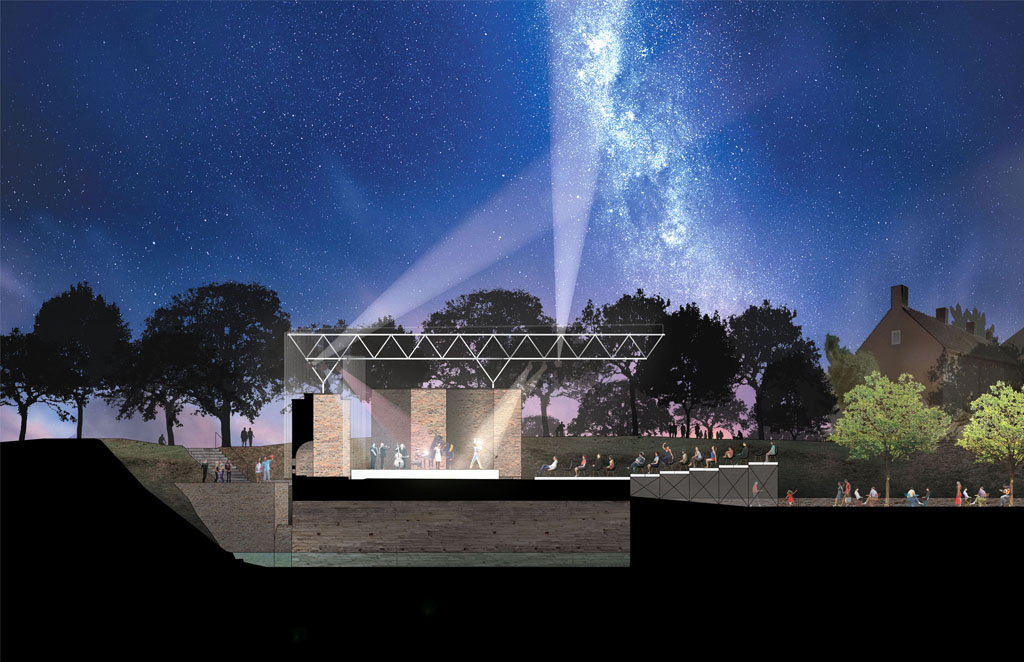

Section of the steel space frames of the open-air theatre in Hulst at night

Steel

JN: Where do you mainly apply Steel to?

BU: Due to the tensile strength of steel and its high strength to weight ratio, I usually consider applying steel to every project that has a larger span. For our school project in Geesthacht the use of steel made it possible for the students, teachers and school staff, to go barrier-free from one building to another and without the need to leave the building and to be exposed to the weather. With the help of the steel structure, it was possible to create an entirely column-free building with a very open and transparent character. With this openness and transparency spaces could be created that can be changed over time with the help of opaque lightweight walls or transparent glass walls. If, for example, many glass walls between the rooms are used, a visually continuous learning and working strip can be created. Is complete openness desired, a completely transparent school can be formed without any wall.

JN: Tell us about the image of Steel that you have. How does the image affect your use of the material?

BU: The image that I have of steel is that of a particular strong material. It stands out especially when it comes to the structure of buildings. This quality I aim to exploit as much as possible to create open spaces without structural destruction to create, in the case of the school in Geesthacht, flexible learning and working landscapes. There – between the rooms – are common areas or common rooms, which allow, together with the connecting corridor, synergies between the different usages, as spaces can be grouped and expanded. In that way, social areas and rooms for independent learning and working are created. Furthermore, the proportions of the classrooms and the possibility of including the adjacent common areas, or group rooms, allow the most diverse forms of teaching. The possibilities range from the traditional teacher lecture to alternative forms of teaching within an open classroom, where students can devote themselves independently to a learning project.

View of the square in Zwolle with the steel fireplace in its centre

JN: Tell us about the pros and cons of Steel Panel.

BU: Apart from steel’s high tensile strength and its high strength per unit mass, I consider the fact that steel can be fabricated and moulded easily into any shape without changing its properties as one of its most interesting qualities. This advantage – and the fact that steel can thus easily be produced off-site and then assembled onsite – we used for an open-air theatre for the Dutch city of Hulst, for which we designed a temporary roof made of steel space frames with thin steel struts that could be easily assembled, disassembled, and stored, together with a temporary stage, temporary stands, and 500 chairs in a 3 metre-high space of about 40m2 surface area. Other advantages of steel include its affordability and durability. One of the biggest disadvantages of steel is probably its weakness when it comes to heat, since steel is not fireproof and loses its properties in high temperatures, which leads to fairly large fireproofing costs. However, when steel is not used structurally, but as a material for urban furniture in public spaces – as we did to create a fireplace for a public square in Zwolle, the Netherlands – this weakness does not matter much. For the square in Zwolle, steel was a good fit, as it represented well the industrial past of the site referring to the chimney of a factory building that was located on the site in the past. With the help of steel a robust place was created, where people could sit, grill and cook.

Title: Eyes Wide Shut”-like Scenes

Author: Bernd Upmeyer

Date: January 2020

Type: Commissioned interview

Publications: Concrete, Stone and Steel (coming soon)

Publisher: DAMDI

Location: Seoul, South Korea

Interviewer: Jinyoun Na